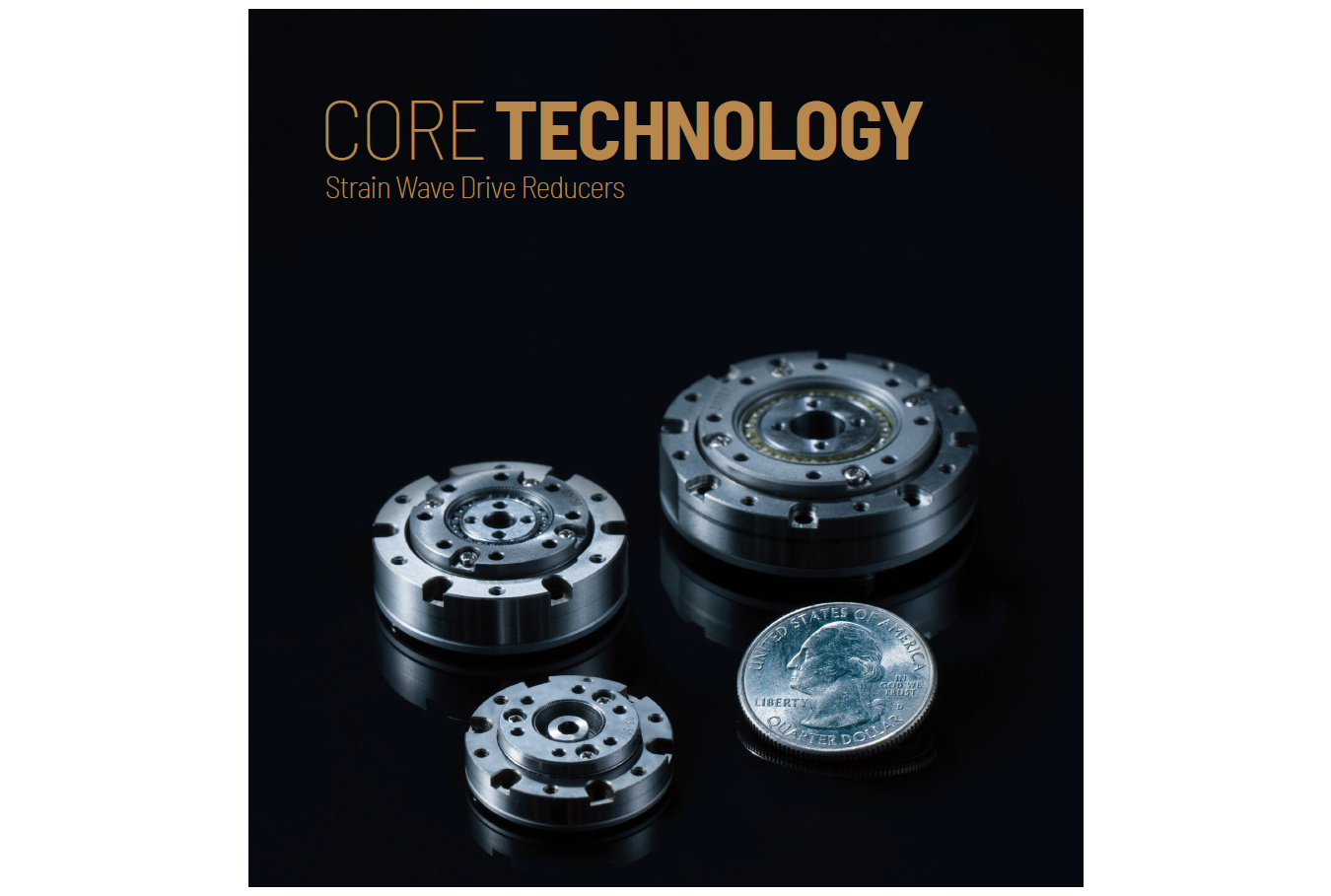

The SHD-03 Ultra-Mini Harmonic Drive is a next-generation 25mm strain wave reducer designed for compact robotic joints, servo actuators, humanoid robots, and advanced micro-mechanisms requiring ultra-high precision and lightweight transmission.

Despite its tiny size—only 7.3mm thick and weighing just 16g—the SHD-03 delivers exceptional torque, ultra-low backlash and stable, smooth motion ideal for professional robotic applications.

✨ Key Features

✔ Ultra-Compact Design

Only 25mm outer diameter and 7.3mm thickness, enabling use in extremely tight installation spaces such as micro-robots, wearable robotics, and precision actuators.

✔ High Precision Strain Wave Transmission

Near-zero backlash (≤20 arcsec), smooth rotation, and high positioning accuracy make it suitable for advanced servo control systems.

✔ High Torque Density

Delivers surprising torque for its size:

-

Rated torque: 0.08–0.13 Nm

-

Peak torque: up to 0.24 Nm

-

Momentary torque: up to 0.50 Nm

✔ High Input Speed Compatibility

Supports up to 10,000 rpm, pairing perfectly with ultra-fast micro servo motors.

✔ Multiple Gear Ratio Options

Optimized ratios for robots and micro-actuators:

30 : 1 / 50 : 1 / 80 : 1 / 100 : 1 / 120 : 1

✔ Industrial-Grade Construction

Precision bearings + steel flex spline ensure long-term durability, stability, and shock resistance.

📐 Technical Specifications

| Parameter | Ratio 30 | Ratio 50 | Notes |

|---|---|---|---|

| Rated Torque (Nm) | 0.08 | 0.13 | @2000 rpm |

| Repeated Peak Torque (Nm) | 0.15 | 0.24 | Continuous |

| Average Torque Limit (Nm) | 0.12 | 0.16 | — |

| Momentary Peak Torque (Nm) | 0.25 | 0.50 | Short time |

| Max Input Speed (rpm) | 10,000 | 10,000 | — |

| Avg Input Speed Limit (rpm) | 6500 | 6500 | — |

| Backlash | ≤20 arcsec | ≤20 arcsec | — |

| Outer Diameter | 25mm | — | — |

| Thickness | 7.3mm | — | — |

| Weight | 0.016kg | — | — |

| Mounting Holes | M1.5 / M2 | — | See drawing |

📦 Package Includes

-

1 × SHD-03 Ultra-Mini Harmonic Drive Reducer (selected ratio)

🔧 Applications

Perfect for:

-

Robotic Joints & Servo Actuators

-

Humanoid Robots & Bionic Arms

-

Micro Robotics & Education Robots

-

Pan-Tilt Gimbals & Camera Stabilizers

-

Precision Automation Systems

-

AI Mobility & Wearable Robotics

-

Medical Devices & Lab Automation

❓ Frequently Asked Questions (FAQ)

Q1: Is this harmonic drive compatible with any motor?

Yes. It works with most coreless motors, brushless DC motors, servo motors, and custom micro actuators.

Q2: What is the maximum load capacity?

0.25–0.5 Nm depending on the gear ratio.

Q3: Does it require lubrication?

It is factory pre-lubricated, maintenance-free in normal use.

Q4: Can it be used for humanoid robot joints?

Absolutely. Its size and precision make it ideal for fingers, wrists, and micro-joint actuators.

⚠ Installation & Safety Instructions

Please follow the guidelines below to ensure correct installation and optimal performance of the SHD-03 Mini Harmonic Drive Reducer.

🔧 1. Lubrication Guidelines

-

If the reducer’s output end is positioned facing downward for extended periods, ensure the lubricant applied to the flexspline’s inner wall cavity fully covers and extends beyond the gear-meshing tooth surface.

-

Proper lubrication prevents wear, overheating, and premature failure.

🔩 2. Assembly & Sealing Requirements

-

Apply a static seal between:

-

the rigid wheel and its connector mounting surfaces

-

the flexspline and its connector mounting surfaces

-

-

This sealing step is essential to prevent grease leakage during operation.

-

Grease loss can lead to insufficient lubrication, resulting in internal damage.

🛠 3. Handling Precautions

-

Do not strike, drop, or apply heavy force to any part of the reducer.

-

Avoid using hard tools or excessive pressure during installation.

-

Improper handling may cause:

-

deformation of precision components

-

reduced torque accuracy

-

shortened service life

-

📞 4. Installation Support

If you experience any issues during installation or testing, please contact our support team. Providing clear photos or videos will help us assist you more efficiently.